Developed by Tezmaksan, CubeBOX systems are designed to seamlessly integrate with any control unit and robot of the user’s choice, irrespective of the manufacturer or communication protocol. These systems are tailored to support the automated loading and unloading of CNC machines, offering a substantial leap in productivity and efficiency.

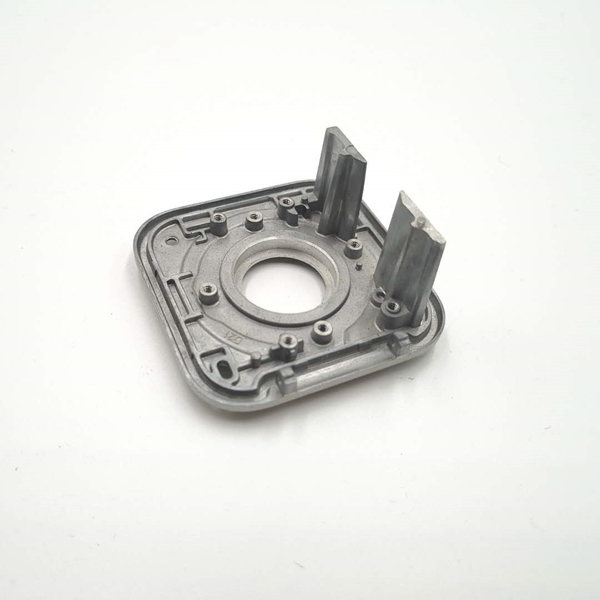

One of the highlighted launches at EMO was the CubeBOX Pallet Pool, also known as Pallet Tower and Pallet Changer. This system automates CNC machining centers with limited floor space, efficiently managing up to 24 pallets and 16 tools with a single unit. Using a 6-axis robot, pallets are arranged in a compact circle in front of the machine, reducing the need for manual operator intervention and enabling round-the-clock, operator-free operation. Cnc Machining Part

Another innovative product showcased at the event was the CubeBOX RT Stacker (RT-S), designed for lathes and vertical machining centers. This system utilizes two pallets for part loading and can tend to one or two CNC machines. Its unique feature allows stacking two pallets on top of each other, increasing throughput without requiring additional factory space.

Tezmaksan also presented the CubeBOX Space Cabinet, featuring three drawers for storing products that are unloaded using a 6-axis robot. This system minimizes the need for frequent restocking, and its ergonomic design allows drawers to be easily positioned for efficient parts supply.

Hakan Aydogdu, General Manager at Tezmaksan, emphasized the significant financial, efficiency, and productivity benefits of automating CNC machine loading and unloading. This automation not only enhances precision and accuracy but also reduces downtime and reliance on operator skill and availability.

The CubeBOX systems rely on RoboCAM, Tezmaksan’s smart automation software, making integration with accompanying robots a straightforward process, even for operators without prior robot programming knowledge. Operators can upload product drawings, and RoboCAM translates them into a language that the robot can understand and execute.

Tezmaksan’s CubeBOX systems, backed by RoboCAM, are pivotal technologies for flexible and serial production systems, a pioneering engineering style that the company has championed for decades. These innovations hold the promise of significantly boosting productivity, with potential returns on investment as short as eight months, making them a compelling choice for manufacturers seeking to optimize their CNC machining operations.

Save my name, email, and website in this browser for the next time I comment.

Aluminium Cnc Machining The story of ‘MAKE IN INDIA’ has reached far and wide. But who are makers of ‘MAKE IN INDIA’? What is their story? ‘Machine Maker’ is a dedicated magazine that seeks to bring the incredible stories…Read More